Metal Finishing & Electroless Nickel for the following industries:

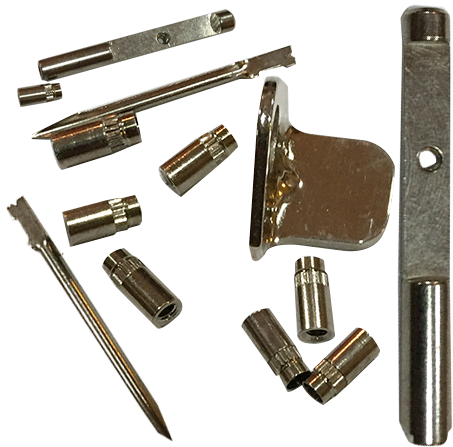

- Mold Components

- Shafts

- Rolls

- Tool & Die

- Machine shop

- Textile

- Food Handling

- Mold Protection

- Tooling Protection

- Commercial

- Hardware

- Machinery

- Office Equipment

- Cutting Tools

- Printing Industry

- Textile parts

- Chemical Processing Industry

- Oil and Gas Industries

National Chromium’s Electroless Nickel is compliant with ELV (automotive), ROHS (electronics), WEEE (electronics) and the Green Initiative (all Industries).

Characteristics of Electroless Nickel, 6-8% (Mid) Phosphorus

- Hardness as plated is 50 to 54 Rc. Hardness can be increased by Baking after plating to 66 to 68 Rc.

- Uniform plating thickness, eliminating edge build-up.

- Excellent Corrosion protection.

- Bright deposit

- Coefficient of Friction is 0.38 (unlubricated) Taber wear, as deposited is 16mg/1,000 cycles

- Melting point is 890 degrees C.

- Nickel-phosphorus alloy coating for a hard, corrosion resistant coating

- Uniform, non-porous layer from .00005″ to .003″ thick

- Available in rack or barrel

Secondary Operations:

We perform Mass Finishing Vibratory Tumbling and Deburring.

National Chromium also sells the media and compounds used in vibratory polishing or deburring.

HIGH QUALITY COATING SERVICES

National Chromium

10 Senexet Rd

Putnam, CT 06260

PH: 860-928-7965

Take advantage of our online resources:

Copyright © 2016 National Chromium Company Inc. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.