Metal Finishing & Hard Chromium for the following industries:

- Mold Components

- Shafts

- Rolls

- Tool & Die

- Machine shop

- Textile

- Commercial

- Hardware

- Machinery

- Office Equipment

- Cutting Tools

Characteristics of Hard Chrome:

- Extends the life of the part.

- Provides very good corrosion protection.

- Coefficient of friction is 0.015 to 0.40 on steel.

- Taber Wear is 2-3 mg/1000 cycles.

- Non-magnetic.

- The melting point of chrome is 1610 degrees C.

- Adhesion strength is 35,000 PSI.

- Ductility is 0.1%.

- Ultra-hard, durable coating used for wear, abrasion and corrosion resistant protection

- Hard Chromium is used to repair worn or mis-machined parts

- Range of thickness from .000020″ to .035”+

- Capacity is 16 feet long and 2 tons

Secondary Operations:

We perform Mass Finishing Vibratory Tumbling and Deburring.

National Chromium also sells the media and compounds used in vibratory polishing or deburring.

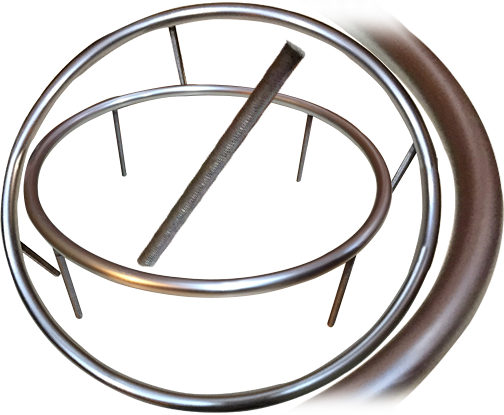

Hard Chromium Coating

Applications for Hard Chrome:

- Used in machinery and mating surface applications because of its hardness.

- National Chromium has extensive experience fabricating fixtures and auxiliary anodes which enables us to efficiently apply chrome on intricate components and surfaces.

- Hard Chrome’s resistance to abrasives results in a longer life for mold components and provides for better mold release characteristics and easier mold cleaning.

- Hard Chrome is used extensively to repair worn or scored machine parts, shafts and cylinders.

- Several cost effective masking methods are utilized to protect surfaces and areas that do not require plating.

HIGH QUALITY COATING SERVICES

National Chromium

10 Senexet Rd

Putnam, CT 06260

PH: 860-928-7965

Take advantage of our online resources:

Copyright © 2016 National Chromium Company Inc. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.